The proper transportation of water along pipelines stands as the essential element for sustainable operations in communities and industries and agricultural sectors. Water pipeline design faces a primary challenge because effective external contamination prevention requires attention. The design process must consider environmental risks because simple pipeline vulnerabilities expose them to contaminants. Every stage throughout a water pipeline’s entire existence needs water quality protective measures during all construction phases as well as ongoing maintenance periods. This paper explores the process of enhancing water pipeline designs through techniques that reduce contamination risks with particular strategies that engineers and designers must focus on.

Proper Pipeline Materials and Seals

Water pipeline materials maintain critical importance as primary elements for stopping contamination during their operations. The selection of suitable materials remains fundamental since it supports both pipeline resistance against damage and water quality preservation. Pipelines based on high-quality non-corrosive components like PVC and stainless steel and polyethylene stop water supply contamination. These materials maintain their structures so external pollutants cannot infiltrate through weakened pathways. The selection of materials which do not support bacterial growth or microscopic organism development proves essential for achieving proper water quality.

The pipeline sections connect through important seals and joints as well. Abnormal gaps in joints along with worn-out gaskets allow external pollutants to enter the system. Advanced sealing solutions such as rubber gaskets and welded joints cut down leakages dramatically. The maintenance of pipeline seals should remain unimpaired during the entire pipeline operational period. The prevention of external contaminants which could affect water supply requires both scheduled analysis of pipeline status and swift maintenance whenever needed.

Design Considerations for Contamination Prevention

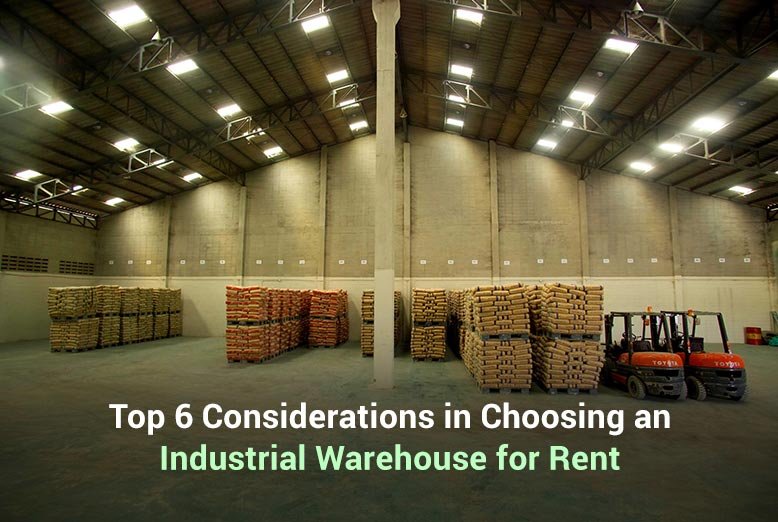

The correct layout of pipelines stands as an important factor for stopping external contamination. Engineers must analyze three crucial pipeline design criteria when constructing pipelines including elevation shifts, soil conditions and the closeness of contamination origins. The installations of pipelines must occur at depth positions that ensure they remain out of contact with surface contaminants specifically in areas prone to flooding or erosion. The planned pipeline route must prioritize areas that do not lead to industrial or agricultural runoff regions since such areas could contain dangerous chemicals or contaminants or heavy metals.

Designers should incorporate shutoff valves together with backflow prevention devices as part of their pipeline systems. By using a butterfly valve as part of water pipeline control systems one can regulate water flow and avoid reverse water movement preventing outside contaminants from entering the pipeline system. The placement of these valves throughout the pipeline system allows designers to achieve both water flow management and contamination risk reduction objectives. The quality of water depends heavily on proper backflow prevention devices because they safeguard water quality during distribution via the system and its interaction with outside environments.

Protecting Water Supply from Surface Contaminants

The exposure of pipelines to surface contact requires supplemental procedures for blocking external contamination entrance. Protective coatings applied as well as casings on pipelines offer a solution to defend the systems against harmful environmental contaminants. The protective layers stop contaminants from reaching the pipe directly and simultaneously minimize pipe corrosion that could introduce vulnerabilities to the system.

A buried pipeline beneath agricultural land encounters the risk of water pollution from seeping pesticides and fertilizers. Protection against environmental hazards comes from applying defensive casings along with corrosion-proof materials. Your pipeline infrastructure that crosses urban areas needs proper planning before it approaches industrial facilities or wastewater treatment plants which serve as possible contamination risks. Additional safety measures consisting of trenching, casing, and impermeable barriers must be applied to defend surface waters from potential contamination.

Monitoring and Maintenance of Pipeline Integrity

A new pipeline requires dedicated maintenance work because this activity stops water contamination from occurring. The inspection of pipelines through regular checks enables operators to notice potential structural weaknesses together with leakages or damage which might create entry points for contaminants into the system. Pipeline maintenance uses modern technology including remote sensors with real-time monitoring systems as it gains increasing popularity. The electronic systems detect contamination risks by promptly identifying drops in pressure together with abnormal temperature changes and water quality fluctuations.

Regular inspections together with maintenance operations should be scheduled for all infrastructure elements including valves and seals to guarantee proper function. Advanced pipeline cleaning methods in combination with flushing applications can eliminate buildup or sediment which allows potential harboring of bacteria or contaminants. Water authorities can reduce external contamination risks in their supply through continuous maintenance investments and modern monitoring technologies to protect consumer water safety.

The prevention of pipeline contamination through optimized water pipeline design demands strategic organizational planning associated with diverse protective strategy execution. The quality of water remains safe because all pipeline management decisions from material selection to system layout to ongoing maintenance monitor contribute to protection. Water utility organizations will achieve long-term safety through pipeline systems by addressing early design process concerns and implementing regular monitoring alongside maintenance investments.