In today’s hyper-connected world, supply chain management, or SCM, is no longer a back-office function but a critical driver of business success. Companies like Amazon and Apple have shown that an agile, efficient, and technologically powered supply chain is a critical competitive advantage; however, how do firms navigate through the complexities of modern supply chains while making their way through globalization, sustainability, and technological disruptions?

This guide explores the fundamentals of SCM and offers a deep dive into emerging trends, actionable strategies, and the evolving role of technology in shaping the future of supply chains.

What is Supply Chain Management?

Supply chain management deals with the coordination and flow of materials, information, and financial flow from suppliers to customers. It ensures that the right product reaches the right place at the right time and at the most appropriate cost.

Core Processes of SCM:

- Planning: Creates forecasted demand and efficient supply chain strategies.

- Sourcing: Identify favorable suppliers and negotiate favorable contracts.

- Manufacturing: The transformation of raw materials into finished products with minimal by-products.

- Logistics: Managing warehousing, transportation, and distribution efficiently.

- Customer Service: Ensuring the timely delivery of products to maintain satisfaction.

An uninterrupted supply chain unifies these processes to produce value for both the end consumer and these businesses.

The Challenges of Modern Supply Chains

1. Consumer Experience Growth

E-commerce has set a new expectation of speed in delivery and transparency. Amazon is a company that sets the standard by claiming next-day delivery as standard.

2. Globalisation and Geopolitical Tensions

Operating across borders is complicated, from paying tariffs to managing suppliers in politically unstable regions. For instance, the U.S.-China trade war served as a crucial reminder for companies.

3. Sustainability Requirements

Ethical and environmental consumerism has become necessary for today’s demand. It reduces emissions, employs the circular supply chain, and sources sustainable materials.

4. Interfering by External Agencies

The COVID-19 pandemic laid bare the fragility of international supply chains. Companies with single-source suppliers suffered greatly, while companies with diversified networks had a smoother ride.

5. Technological Disruptions

New technologies and innovations like blockchain, AI, and IoT are revolutionizing supply chain operations but require significant investment and skilled personnel for their efficiency.

Key Trends Shaping the Future of SCM

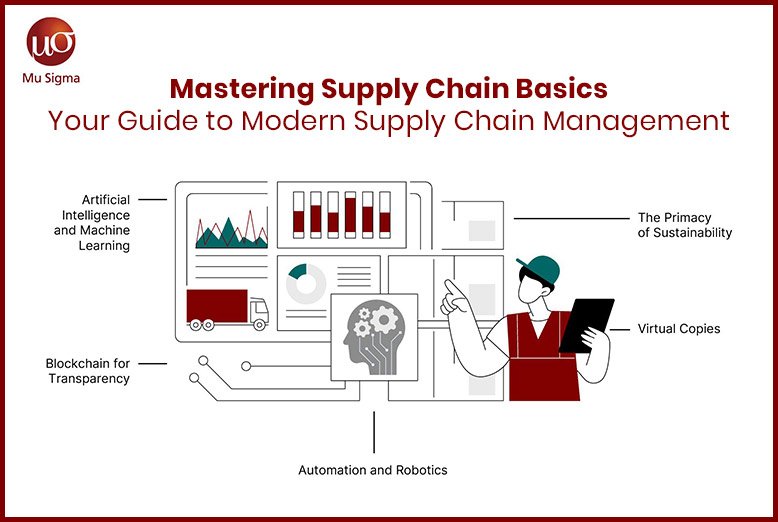

1. Artificial Intelligence and Machine Learning

AI-powered tools are transforming supply chain planning. For example, predictive analytics enables companies to forecast demand with greater accuracy, minimizing overproduction and stockouts.

2. Blockchain for Transparency

Blockchain technology has been applied to improve traceability. Walmart uses blockchain technology to trace foodstuffs from every stage of the supply chain, making its food products much safer and fresher by minimizing waste.

3. The Primacy of Sustainability

Companies like IKEA and Patagonia have committed to creating circular supply chains by reusing and recycling materials, reducing their environmental footprint.

4. Virtual copies

Digital twins—virtual replicas of physical supply chains—allow companies to simulate and optimize operations before implementing changes.

5. Automation and Robotics

Online retailers such as DHL and Amazon use automated warehouses and robotic delivery systems to operate efficiently and reduce their labor costs.

Why is Supply Chain Management Crucial for Businesses?

A well-optimized supply chain is always the backbone of operational efficiency and customer satisfaction. Follow:

- Cost savings: This helps reduce any firm’s cost by making its processes more streamlined and without waste.

- Customer Retention: Systematic deliveries and readiness create consumer confidence and loyalty.

- Resilience: Agile supply chains are responsive to disruptions and hence minimize losses.

It is proven by companies like Apple that a superior supply chain can create unbeatable products and services.

Mastering the Fundamentals of Supply Chain Management: Approaches

Mastering supply chain management requires a strategic approach and the use of modern tools. Here are some practical steps:

1. Building the Supply Chain

Differentiate suppliers and have plans for disruption prevention. Utilize tools such as SAP Integrated Business Planning for better visibility.

2. Leverage Technology

Buy supply chain software with real-time tracking, predictive analytics, and automated processes. Some good examples are Oracle SCM Cloud and Microsoft Dynamics 365.

3. Adopt Environment-Friendly Practices

Evaluate the carbon footprint of your supply chain and identify areas for improvement. Implement simple solutions, such as optimizing transportation routes, to make a significant impact.

4. Supplier Collaboration up

Maintain your relationships with suppliers through open communication and equitable contracts. Platform solutions such as Ariba Network can facilitate engagement with suppliers.

5. Build Your Workforce

Prepare your team with the skills for the management of modern supply chains. Some examples include APICS Certified Supply Chain Professional.

Leveraging Data Analytics in Supply Chain Management

Data analytics has transformed supply chain management, turning traditional processes into highly optimized, data-driven operations. By enabling companies to interpret vast amounts of data from multiple sources, analytics helps streamline operations, reduce costs, and improve decision-making at every stage of the supply chain.

Demand Forecasting

Finally, with predictive analytics, customers’ needs can be forecasted by integrating sales history, competitor analysis, and other factors such as cyclicality. This helps:

- Coordinating the production schedule with fluctuations in demand.

- Most importantly, avoid stockouts and minimize overstocking.

- Reduce loss and enhance productivity.

Inventory Optimization

Analytics tools track inventory in real-time, enabling companies to:

- Calculate such key parameters as reorder points of raw material and finished products.

- Reduce holding costs by identifying products that take time to sell out.

- Increase productivity in a warehouse through proper arrangement of the stocks.

Improvement of Efficiency in Transportation as well as Logistics

Structural insights enable one to determine the best strategic routes for carriage, thus reducing the time and the costs of fuel. With real-time tracking, companies can:

- Divert cargo to counterbalance delivery time occurrences or climatic factors.

- Compare information on fuel consumption and traffic to work towards efficient fleet operation.

- Inform the customers on delivery periods to improve on the amount of trust you get from the customers.

Risk Management

Supply chains face numerous risks, some of which can be mitigated with the aid of analytics tools.

- Hypothesize weaknesses through quantitative and qualitative analysis time series.

- Evaluate supplier performance to be sure there will be no more sudden breaks.

- Creating plans on what action should be taken in case a bad situation arises.

Examining Zara’s Flexible Supply Chain

One of the brightest performance areas in supply chain management is Zara. Its very flexible supply chain enables the firm to design, produce, and distribute new products in just 15 days. By locating production near its European headquarters and leveraging real-time data from retail outlets, Zara can quickly adapt to changing consumer preferences and minimize overstock and discounts.

Conclusion: Resolving the Future of Supply Chain Management

Supply chain management proficiency requires a focus on both traditional approaches and modern development. Better companies that invest in technology upgradation, sustainability practices, and strong networks better compete with the challenges and changing opportunities. In a contemporary landscape characterized by the rapid evolution of customer expectations, an optimized supply chain transcends just being a business operation—it is a significant competitive advantage. Therefore, before developing it effectively in terms of value, resilience, and growth opportunities, it is necessary to understand its foundational principles.

Also Read: How RFID Technology is Shaping Supply Chain Management