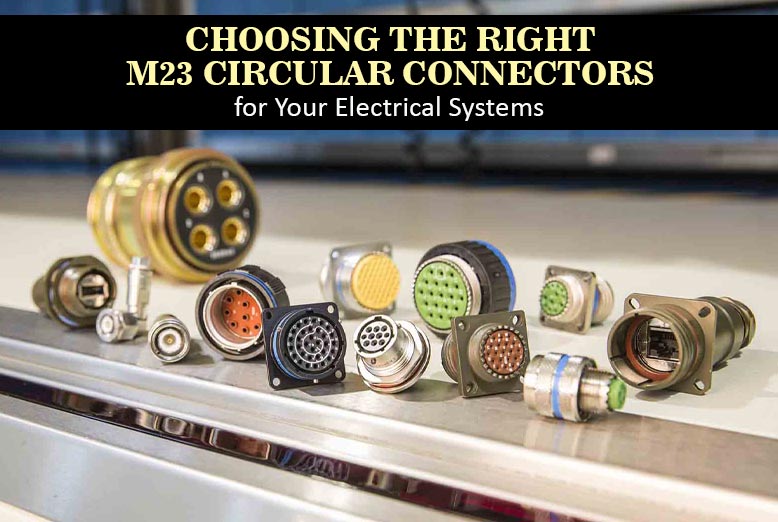

In the world of electrical systems, choosing the right connectors is crucial for ensuring reliability, efficiency, and safety. M23 circular connectors have emerged as a popular choice due to their robust design, versatility, and ability to handle various environmental conditions. Whether you’re designing a new system or upgrading an existing one, understanding the key features and considerations of M23 circular connectors will help you make informed decisions.

What are M23 Circular Connectors?

M23 circular connectors are part of a family of connectors known for their circular shape and threaded coupling mechanism. They are used primarily in industrial automation, machinery, and other applications where robust and reliable electrical connections are essential. These connectors typically consist of multiple pins (contacts) housed within a circular shell, which is designed to withstand mechanical stress, environmental factors, and electromagnetic interference (EMI).

Key Features and Benefits

- Robust Construction: M23 connectors are built to withstand harsh industrial environments. They are often made from durable materials such as metal alloys or high-grade plastics, ensuring resistance to impacts, vibrations, and corrosion.

- Versatility: These connectors support a wide range of applications, including power transmission, signal transmission, data transfer, and sensor connections. They come in various configurations, allowing for flexibility in design and integration.

- IP Ratings: In industrial settings, protection against dust, water, and other contaminants is crucial. M23 connectors typically come with IP67 or higher ratings, indicating their resistance to dust ingress and water immersion under specified conditions.

- EMI Shielding: Electrical interference can disrupt signals and affect system performance. M23 connectors often feature shielding options that minimize electromagnetic interference, ensuring reliable data transmission and signal integrity.

- Easy Installation: The threaded coupling mechanism of M23 connectors facilitates quick and secure installation, reducing downtime during assembly and maintenance activities.

- Compatibility: They are compatible with various cable types and sizes, accommodating different current ratings and voltage levels as per application requirements. For a comprehensive selection of M23 circular connectors tailored to various industrial requirements, consider exploring options that provide these critical features.

Factors to Consider When Choosing M23 Circular Connectors

- Application Requirements: Determine whether you need connectors for power transmission, signal transmission, or data communication. Select connectors that match your specific application needs in terms of current rating, voltage rating, and signal integrity requirements.

- Environmental Conditions: Consider the operating environment—temperature variations, exposure to chemicals, dust, water, and mechanical stress. Choose connectors with appropriate IP ratings and material compositions that can withstand these conditions.

- Connector Type and Configuration: M23 connectors come in different types, such as male and female connectors, panel-mount, and cable-mount variants. Select the type and configuration that best suits your installation and connectivity requirements.

- Number of Contacts: Determine the number of pins or contacts required based on the complexity of your electrical system. Ensure that the connector has sufficient contacts for all necessary connections without compromising on space or performance.

- Durability and Reliability: Assess the connector’s durability features, including materials used, mechanical robustness, and reliability in maintaining electrical continuity over the connector’s lifespan.

- Ease of Maintenance: Consider connectors that are easy to install, maintain, and replace when necessary. Quick-disconnect features and compatibility with standard tools can simplify maintenance procedures and reduce downtime.

- Cost Considerations: While quality and reliability are paramount, consider the overall cost-effectiveness of the connectors, including initial purchase cost, installation costs, and long-term maintenance expenses.

Applications of M23 Circular Connectors

M23 circular connectors find applications across various industries and sectors:

- Industrial Automation: Used in machinery, robotics, and automated production lines for power and signal transmission.

- Transportation: Applied in vehicles, trains, and aircraft for communication, control systems, and power distribution.

- Renewable Energy: Used in solar and wind energy systems for connecting power cables and control circuits.

- Medical Equipment: Utilized in diagnostic devices, imaging systems, and patient monitoring equipment for reliable data transmission.

- Telecommunications: Applied in network infrastructure for connecting fiber optic cables and communication systems.

Conclusion

Choosing the right M23 circular connectors for your electrical systems involves evaluating technical specifications, environmental factors, and application requirements. By selecting connectors that offer robust construction, versatility, and compatibility with your system’s needs, you can ensure reliable performance, safety, and longevity. Whether you’re designing new installations or upgrading existing ones, investing in high-quality connectors tailored to your specific requirements is essential for achieving optimal system performance and operational efficiency.

Also Read: New electric cars in India