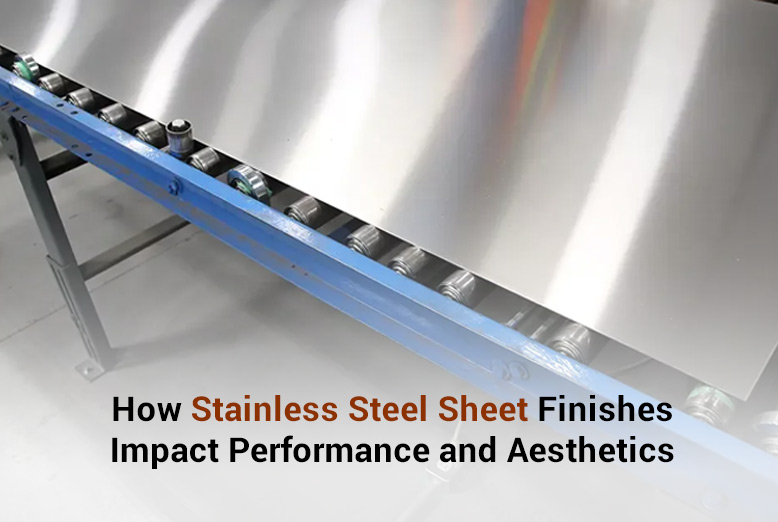

Stainless steel sheet finds extensive use in commercial and industrial projects because it demonstrates exceptional durability together with corrosion protection and clean elegant design. The selection of finish makes a substantial impact on functional properties in addition to appearance quality of stainless steel sheet. Field knowledge regarding stainless steel sheet finishes enables manufacturers and businesses to select proper materials efficiently for their applications.

Stainless Steel Sheet Finishes In Different Environments

The functional performance of stainless steel sheet materials depends heavily on the selected sheet finish. The fight against bacterial growth in facilities like medical centers and food processing plants becomes easier because of a smooth stainless steel finish that resists accumulation. Every architectural exterior needs a finish that combats fingerprints and scratches so the appearance remains attractive across all harsh environmental challenges.

The material’s longevity against corrosion depends on choosing the best finish. Standard finishes showing noticeable grain patterns will attract moisture together with contaminants which speeds up metal deterioration especially in demanding conditions. Selecting finishes with added corrosion protection becomes essential for areas that encounter chemicals and extreme temperatures along with high humidity conditions because it boosts longevity and minimizes maintenance spending.

Stainless Steel Sheet Finishes And Maintenance

Multiple finishes need distinct care routines to stay functional together with maintaining their presentation quality. The visible fingerprints together with smudges and scratches become more evident when stainless steel finishes achieve high levels of polish such as mirror or brushed textures so regular cleaning becomes necessary to preserve their appearance. Matte and textured surface treatments enable better hiding of minor flaws thus providing a beneficial selection whenever heavy traffic exists.

The final warranty of stainless steel sheet depends heavily on the selection of its finishing treatment. Stainless steel sheets receive two types of finish enhancement that boost their wear resistance; bead-blasted combined with mechanically textured finishes. These finishes find their main use in heavy industrial environments where materials experience continuous mechanical wear and stress. The appropriate selection of finish will help stainless steel sheets stay both practical and attractive in their intended use areas.

Stainless Steel Sheet Finishes And Aesthetics

The aesthetic value plays an essential role among many users who choose stainless steel sheets for their applications. The required visual outcome determines the choice of specific finishes which architects use during their projects and in interior designs alongside consumer product creators. A mirror-like finish beautifully reflects modernity through its reflective quality thus achieving two functions of spreading brightness and creating eye-catching decoration. The brushed and satin finish produces sophisticated appearances that suit modern design schemes.

A stainless steel finish affects its reaction with adjacent materials together with the way light reflects off its surface. A system selected wisely in retail spaces and restaurants alongside office facilities will help enhance design features while building a pleasant atmosphere in the space. Categories of finishes should be selected to optimize stainless steel sheet performance since they maintain useful properties while delivering visual appeal to intended designs.

Stainless Steel Sheet Finishes And Fabrication

Stainless steel fabrication processes become easier as a result of the selection of sheet surface finishes. The manufacturing process demands that certain finishes need preliminary treatment for welding or forming but other finishes demonstrate better tolerance to manufacturing steps. A polished finish simplifies post-weld cleaning operations although rough surfaces need more extensive finishing work because refinement is necessary for achieving uniform appearance.

The finish of the material impacts its stress-related behavior during bending and cutting and stamping procedures. Some surface finishes prove more susceptible to manufacturing damage during processes that cause production delays together with cost increases. A finish selection matching production techniques leads to faster workflow and prevents additional work on the project.

Choosing The Right Stainless Steel Sheet Finish

Various applications together with industrial specifications need specific surface finishes to fulfill performance requirements as well as legal criteria. The food and beverage industry requires smooth and non-porous finishes for strict sanitation standards that avoid contaminations. A marine environment demands stainless steel finishes which demonstrate high corrosion protection because materials must withstand persistent saltwater conditions and high humidity.

The automotive industry and aerospace sector together with manufacturing use finished stainless steel sheets to combine mechanical strength with visual appearance standards. Organizations who select finishes compatible with their operational sector requirements will obtain optimal stainless steel sheet performance in addition to adhering to industrial protocols.

Cost Considerations Of Stainless Steel Sheet Finishes

The selection of finish for stainless steel sheets determines the total expenses of the project. Finishing processes which need comprehensive treatment result in elevated material expenses as well as higher labor costs. Stainless steel sheets with high-polish and specialty finishes need additional treatment processes that elevate their total cost above standard mill or brushed finish alternatives. A business should analyze how much value they obtain from their chosen finish in order to decide which solution delivers the best return on investment.

Businesses should estimate costs that will be needed for long-term maintenance during their decision-making process. Material modifications with high initial expenses lead to decreased maintenance expenses since these finishes provide better protection against wear and natural hazards. Proper decision-making through understanding of investment costs alongside maintenance requirements allows organizations to achieve harmony between visual appeal and operational qualities as well as financial implications.

Businesses and manufacturers gain the ability to choose appropriate stainless steel sheet finishes through their understanding of how these finishes affect both performance and aesthetics. A suitable finish selection for industrial, architectural and commercial purposes ensures both durability along with easy care and aesthetic quality. The combination of environmental conditions and fabrication requirements and cost evaluation allows users to achieve optimal stainless steel sheet performance that fulfills functional needs with aesthetic objectives.

Also Read: Introduction to Steel Surface Treatment via Powder Coating